Loading video of roller crusher

The roller crusher primarily crushes materials through the compression and shearing action of two relatively rotating rollers. Materials enter the gap between the rollers and are crushed through compression and shearing. It is suitable for crushing fluorite and offers convenient particle size adjustment, enabling control over the size of the discharged material. However, there are issues related to production output. The processing capacity of the roller crusher is relatively moderate. For large-scale production, multiple units or larger models may be required.

]]>

The molybdenum ore beneficiation process includes several key stages that ensure efficient mineral recovery and high-grade concentrates. Here’s an overview:

1. Crushing and Screening

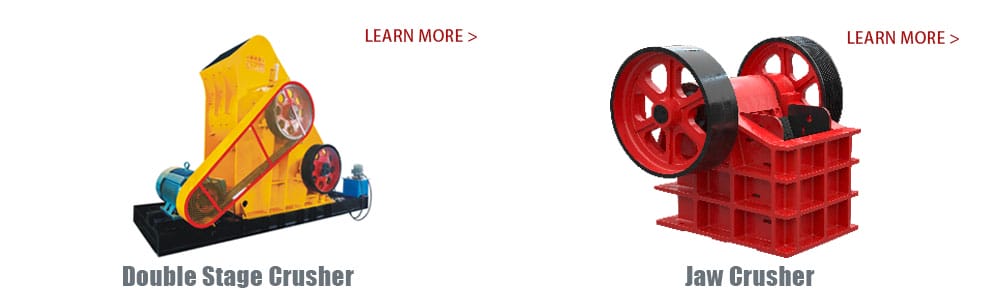

- Molybdenum ore is first crushed using jaw crushers or double roller crushers to reduce large chunks into smaller, manageable sizes.

- Vibrating screens remove oversized particles, ensuring uniform material for grinding.

2. Grinding and Classification

- Crushed ore is sent to ball mills for fine grinding, turning it into fine powder.

- Spiral classifiers or hydrocyclones then classify the ground material, separating fine particles for the next step.

3. Flotation

- Flotation is the core process for molybdenum ore beneficiation. By adding flotation reagents, molybdenum minerals separate from impurities.

- Froth containing molybdenum rises to the surface, forming the concentrate, while tailings are discharged.

4. Concentration and Filtration

- The flotation concentrate undergoes thickening to remove excess water using a thickener.

- Further dehydration is achieved with a filter press, resulting in low-moisture molybdenum concentrate.

5. Drying and Packaging

- The filtered concentrate is dried in a rotary dryer.

- Finally, the dry molybdenum concentrate is packaged and prepared for shipment or market use.

Process

Recommended Equipment

- Crushing: Double Roller Crushers, Jaw Crushers

- Grinding: Ball Mills

- Classification: Spiral Classifiers, Hydrocyclones

- Flotation: Flotation Machines

- Dehydration: Thickeners, Filter Presses

The molybdenum ore beneficiation process includes several key stages that ensure efficient mineral recovery and high-grade concentrates. Here’s an overview:

1. Crushing and Screening

- Molybdenum ore is first crushed using jaw crushers or double roller crushers to reduce large chunks into smaller, manageable sizes.

- Vibrating screens remove oversized particles, ensuring uniform material for grinding.

2. Grinding and Classification

- Crushed ore is sent to ball mills for fine grinding, turning it into fine powder.

- Spiral classifiers or hydrocyclones then classify the ground material, separating fine particles for the next step.

3. Flotation

- Flotation is the core process for molybdenum ore beneficiation. By adding flotation reagents, molybdenum minerals separate from impurities.

- Froth containing molybdenum rises to the surface, forming the concentrate, while tailings are discharged.

4. Concentration and Filtration

- The flotation concentrate undergoes thickening to remove excess water using a thickener.

- Further dehydration is achieved with a filter press, resulting in low-moisture molybdenum concentrate.

5. Drying and Packaging

- The filtered concentrate is dried in a rotary dryer.

- Finally, the dry molybdenum concentrate is packaged and prepared for shipment or market use.

Process

Recommended Equipment

- Crushing: Double Roller Crushers, Jaw Crushers

- Grinding: Ball Mills

- Classification: Spiral Classifiers, Hydrocyclones

- Flotation: Flotation Machines

- Dehydration: Thickeners, Filter Presses

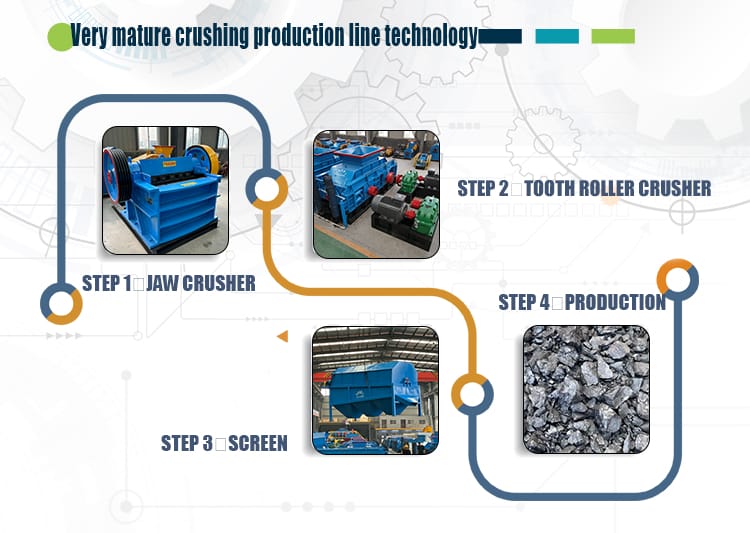

We recommended a complete crushing solution: jaw crusher, double roller crusher, and vibrating screen. The jaw crusher reduces the 10 cm stones to about 3 cm. Next, the double roller crusher processes the material into 3 mm sand. Finally, the vibrating screen separates the finished product by size.

Our factory has a trial production line with the same configuration. The customer personally tested the crushing effect and saw the equipment’s operation. The rotary drum screen separated the materials into three grades: 3-5 mm, 1-3 mm, and below 1 mm. This allowed him to observe the precise grading of crushed materials.

The following day, we took him to a local production site. This site handled similar raw materials and output sizes as his requirements. He observed the crushing performance and product quality firsthand. By the end of his visit, he was highly satisfied with the equipment and our service.

For pebble sand-making solutions, visit us and test our advanced equipment. We welcome all sand plant owners to explore our reliable crushers.

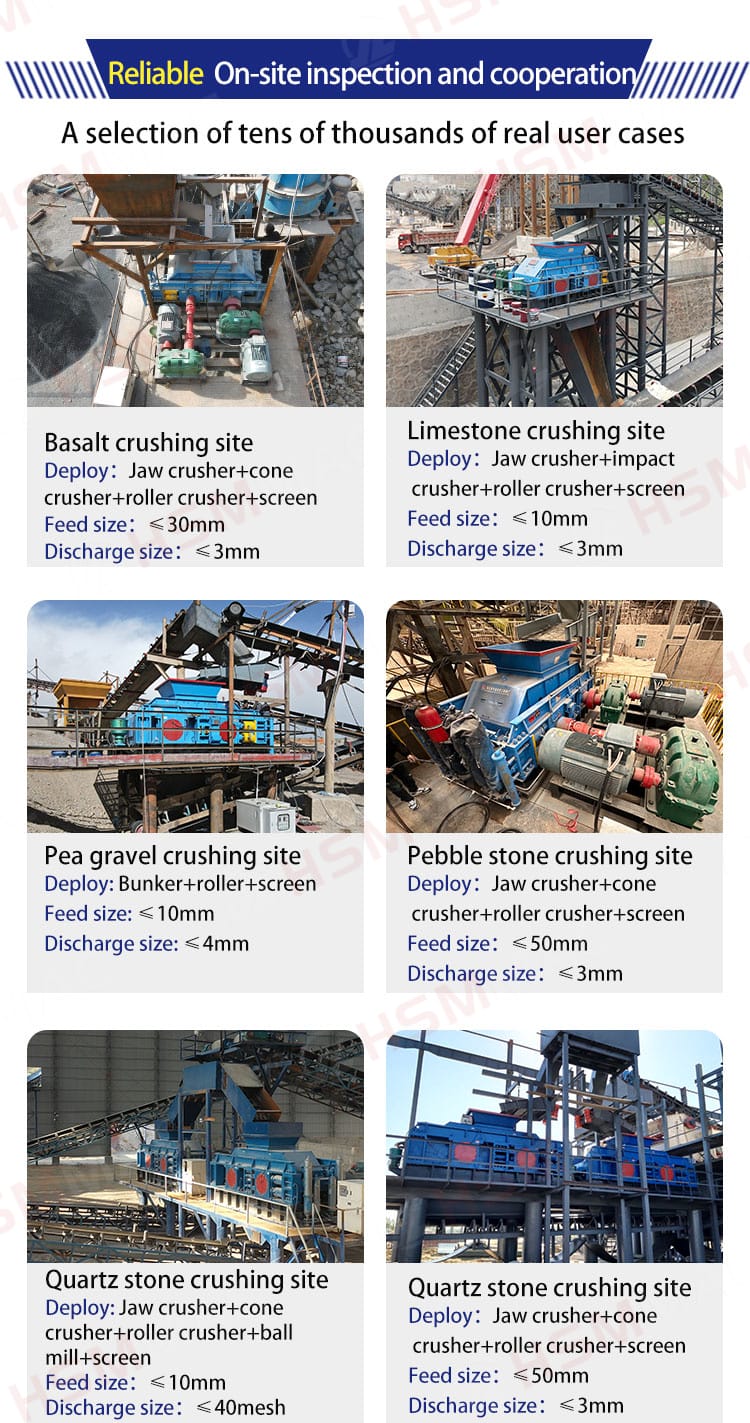

Applications of Huashengming double roller crusher production line

Huashengming’s range of double roller crusher production line meets the needs of various industries. Whether for large-scale projects or small applications, our machines deliver consistent results.

Limestone

Limestone processing requires the right equipment. Huashengming designs durable and efficient limestone crushers tailored to your specifications.

Gypsum

We offer custom crushers to process both synthetic and natural gypsum rock into the desired product size.

Bauxite and Barite

Our engineers design robust crushers for reducing bauxite and barite into the required dimensions.

Other Materials

Our machines also handle sandstone, gravel, and other industrial materials. We specialize in creating custom solutions for all rock types.

Why Choose Huashengming’s Crushers?

Huashengming Heavy Industry takes pride in offering high-quality machines for crushing stone. No matter the project size, our crushers deliver reliable performance.

Key Features:

- Ability to crush a wide variety of materials.

- Durable construction that lasts for decades.

- Custom designs tailored to your specific needs.

Explore our extensive catalog today and discover why Huashengming Heavy Industry is your trusted partner for stone crushing solutions.

]]>Firstly, the double roller crusher is the core machine, delivering precise crushing for increased production rates. Next, the vibrating screen evenly sorts materials, ensuring uniform particle sizes across different specifications. Then, the sand washer thoroughly cleans the materials, removing impurities for higher quality sand. Finally, the dewatering screen dries the sand, securing optimal end-product quality.

This production line was meticulously designed and assembled to ensure seamless machine cooperation. With such a well-integrated setup, customers can swiftly begin operations and achieve optimal output. This efficient sand production line is not only productive but also easy to maintain, promising high returns on investment.

Background

A large construction materials company had been using traditional crushing equipment for years. However, with increasing demand, they began facing several issues: low production efficiency, high energy consumption, and frequent equipment breakdowns. To address these problems, they decided to upgrade their machinery by introducing a twin tooth roll crusher.

Challenges

The existing crushing equipment had low production rates and required frequent maintenance, increasing downtime. Additionally, the limited capabilities of the machines meant that they couldn’t efficiently handle different types of raw materials, leading to waste and delays.

Solution: Twin Tooth Roll Crusher

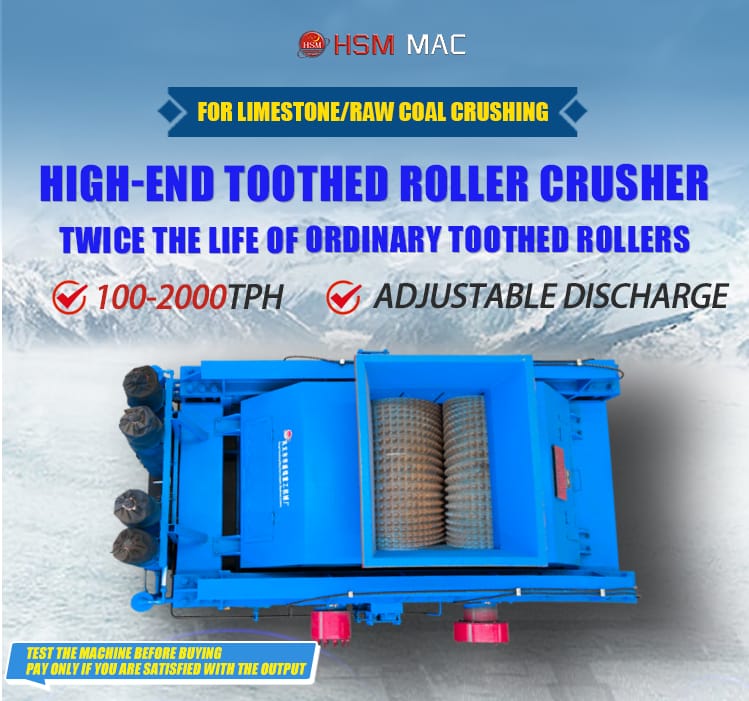

After a detailed analysis of the company’s needs, we recommended the Tooth Roll Crusher as the optimal solution. Here are the key advantages of this equipment:

- High Crushing Efficiency: The dual-tooth roll design efficiently crushes materials with minimal energy consumption, leading to significant improvements in production capacity.

- Versatility: Whether processing hard rocks or wet sand and gravel, the twin tooth roll crusher easily adapts to various raw materials, ensuring consistent output.

- Low Maintenance Costs: The simple structure and efficient operation of the twin tooth roller crusher reduce the frequency of repairs and maintenance, leading to lower operational costs.

- Precise Output Control: By adjusting the gap between the rollers, companies can control the size of the final product, resulting in higher quality sand and gravel.

Results: Significant Efficiency Gains

After implementing the tooth roller crusher, the company experienced a noticeable increase in production efficiency. The production output rose by over 30%, and energy consumption dropped by around 15%. More importantly, the machine’s low maintenance requirements reduced downtime and costs.

Customer Feedback

The company noted that the introduction of the twin tooth roll crusher not only boosted production efficiency but also strengthened their competitive position in the market. The reliability and flexibility of the equipment enabled them to generate higher profits and better meet customer demands.

Conclusion

This case study highlights the importance of selecting the right equipment to improve production efficiency. The Tooth Roller Crusher provides excellent performance, delivering high output and low operational costs, making it a valuable asset for sand and gravel producers.

If you’re facing similar challenges and want to boost your production efficiency, consider upgrading to a twin tooth roll crusher. Contact us for more information, and let us tailor a solution to fit your needs.

]]>

Powerful Configuration for Optimum Performance

This machine isn’t just any model; it’s the enhanced version. It comes equipped with two 55 kW motors. These motors deliver consistent and robust power, ensuring smooth operation. Moreover, the machine features two 280 CLY reducers. These components work together to provide precise speed control, which is essential for achieving the desired fine sand quality.

Roller Sand Making Machine Designed for Fine Sand Production

Meeting customer requirements is a priority. This machine is specifically configured for producing fine sand, making it perfect for the Jamaican customer’s needs. It processes raw materials efficiently, transforming them into high-quality sand. With its advanced hydraulic system, the roller sand making machine offers a seamless production process.

Why Choose a Roller Sand Making Machine?

Roller sand making machines are known for their durability and precision. They offer several advantages:

- High efficiency in sand production.

- Low energy consumption due to optimized design.

- Easy maintenance with accessible parts.

These features make them a preferred choice for businesses aiming to produce high-quality sand. Furthermore, the machine’s hydraulic design ensures stability, even during continuous operation.

A Custom Solution for a Growing Business

This shipment to Jamaica demonstrates the adaptability of the roller sand making machine. It shows how different configurations can meet specific customer needs. The fully hydraulic system and powerful motors ensure that the machine performs well, even in demanding environments. With this setup, the customer in Jamaica can now produce fine sand efficiently and reliably.

Conclusion

The roller sand making machine is more than just a piece of equipment. It’s a solution for businesses that need precision and efficiency in sand production. With its custom configurations, it’s ready to meet diverse demands. Whether you’re producing sand for construction or other applications, this machine offers the reliability and performance you need.

Huashengming Heavy Industry recently delivered two customized Gypsum Double Tooth Roller Crushers, each measuring 610*400mm. These crushers were specifically tailored for a client, Mr. Ma, who needed an efficient solution for processing gypsum raw materials. With the added material-breaking function under the rollers, these crushers provide enhanced performance, making them the ideal choice for gypsum processing.

Why Choose a Gypsum Tooth Roller Crusher?

The Gypsum Double Tooth Roller Crusher offers several advantages over conventional crushers. It efficiently crushes gypsum into fine particles with minimal dust. Moreover, this crusher allows for precise control over the final particle size, ensuring consistency in output.

Key Benefits of the Huashengming Gypsum Crusher

- Enhanced Efficiency: The dual rollers offer continuous crushing, reducing downtime.

- Durable Design: The rollers are made from high-quality wear-resistant materials, extending the crusher’s service life.

- Customizable Features: Huashengming can add specific functions, such as material-breaking enhancements, to meet unique customer needs.

Customized to Meet Gypsum Processing Needs

Mr. Ma’s customized crusher is a perfect example of Huashengming’s adaptability. By integrating additional functions, the Double Tooth Roller Crusher optimizes gypsum processing efficiency. This solution ensures high output and reduced operational costs, making it ideal for businesses focused on gypsum material processing.

Conclusion

For businesses looking to improve gypsum crushing efficiency, the Gypsum Tooth Roller Crusher?by Huashengming offers the perfect solution. With customized options and reliable performance, it ensures better output and operational convenience. Contact Huashengming today to learn more about their tailored crushing solutions!

Product parameter

|

Specification and model

|

Roll diameter (mm) |

Feed size (mm) |

Productive capacity (t/h) |

|

2PGT400×250

|

φ400

|

≤25

|

2-10

|

|

2PGT400×400

|

φ400

|

≤25

|

5-12

|

|

2PGT610×400

|

φ610

|

≤30

|

5-20

|

|

2PGT750×500

|

φ750

|

≤30

|

10-40

|

|

2PGT800×600

|

φ800

|

≤40

|

12-50

|

|

2PGY800×800

|

φ800

|

≤40

|

40-50

|

| 2PGY800×1000 |

φ800

|

≤40

|

50-80

|

|

2PGY1000×800

|

φ1000

|

≤40

|

50-80

|

|

2PGY1000×1000

|

φ1000

|

≤40

|

80-100

|

|

2PGY1200×1000

|

φ1200

|

≤60

|

100-120

|

|

2PGY1200×1200

|

φ1200

|

≤60

|

120-150

|

|

2PGY1500×1000

|

φ1500

|

≤80

|

150-200

|

|

2PGY1500×1200

|

φ1500

|

≤80

|

200-250

|

|

2PGY1800×1000

|

φ1800

|

≤100

|

250-300

|

|

2PGY2000×1200

|

φ2000

|

≤120

|

300-400

|

Huashengming Heavy Industry is loading and shipping a 750*500mm fully hydraulic roller crusher and a 1236-type vibrating screen to customers in Shanxi, China. These machines will be used for crushing granite and making sand. Additionally, the roller crusher is capable of crushing dolomite, functioning as a dolomite sand maker. We wish Mr. Sun a prosperous business with these new tools.

Advantages of the Dolomite Double Roller Sand Making Machine:

- Energy-efficient: The machine operates with low energy consumption. It maintains high production efficiency, making it ideal for large-scale dolomite processing.

- Adjustable particle size: The gap between the rollers is adjustable. This allows operators to control the size of the output sand and meet various engineering needs.

- Easy maintenance: The machine has a compact structure. It is easy to maintain, which minimizes downtime and increases production efficiency.

- Environmentally friendly: During operation, the machine produces little dust and noise. This ensures compliance with environmental regulations.

Dolomite Sand Maker Applications:

The dolomite double roller sand maker is used in construction materials, glass, ceramics, and metallurgy industries. Besides,It is especially useful for crushing dolomite into sand. In addition to dolomite, the machine can also process other medium-hard minerals like limestone and granite.

Huashengming Heavy Industry manufactures various models of this machine. These models cater to different production capacities and particle size requirements. The machines offer reliable performance in dolomite processing. For more details on specifications or pricing, feel free to contact us.

Introduction of dolomite sand making machine:Roller Crusher

Related machine recommendation:Granite roller sand making machine

Related case recommendation:Huashengming Ships 1000*1000mm Double Roller Crusher to Brazil

]]>

Huashengming Heavy Industry recently shipped a 1000*1000mm double roller crusher to Brazil. This shipment demonstrates Huashengming’s global reach and product reliability. The crusher was carefully packaged to ensure safe transport over long distances.

The Brazilian client required a robust solution for material reduction. After thorough research, they selected Huashengming’s advanced double roller crusher. The crusher’s design is ideal for reducing various hard materials efficiently.

Huashengming’s team coordinated every step of the process, from production to shipment. Timely delivery was a key priority, and the company met the client’s expectations. The successful shipment highlights Huashengming’s commitment to global customer satisfaction.

This project showcases Huashengming’s capability to serve clients worldwide. The 1000*1000mm double roller crusher is now ready to contribute to the Brazilian client’s operations.

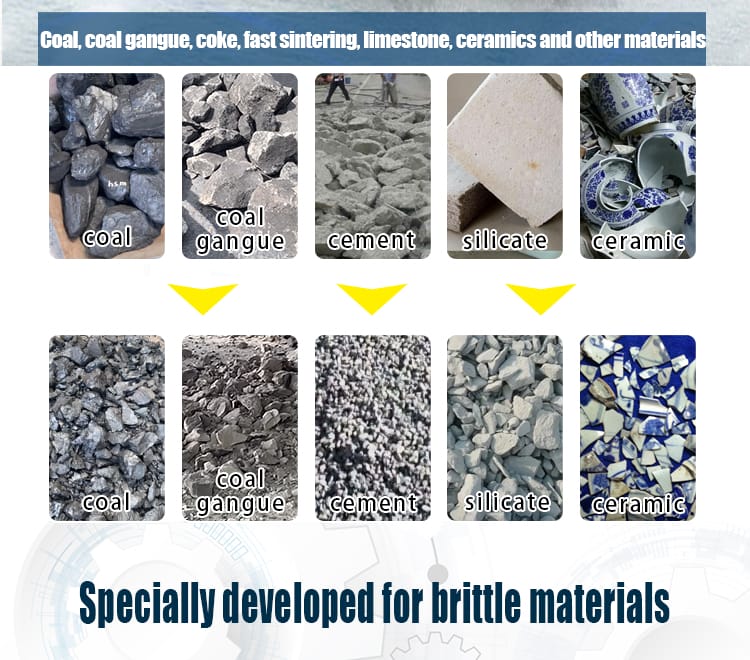

Applicable materials:Coal, River pebble, calcite, quartzite, marble, pebble, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, diabase, granite, basalt and so on

Application scope:?Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

The large double roller crusher evolved from the hydraulic roller crusher. The hydraulic structure controls pressure between the rollers accurately. It guarantees consistent pressure during long-term continuous operation. Therefore, it maximizes the grinding system’s production capacity. Typically, the output increases by 30% to 40%. Moreover, the energy consumption decreases by 20% to 30%.