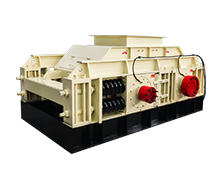

The coal crusher?machine is based on the original double-roll crusher, utilizing spiked rollers to crush materials, hence it is also known as a spiked roller crusher or coke crusher.The claw-type crusher (double-tooth roller crusher) is primarily suited for coarse and medium crushing of brittle lump materials in mining, metallurgy, chemical,and coal industries. It handles large feed sizes with adjustable output particle size and can crush materials with compressive strength ≤160 MPa. Particularly in thecoal industry, the double-tooth roller crusher?is used to crush coke, raw coal, and coal gangue. After impurity and iron removal, gangue removal is unnecessary,allowing direct crushing. The crushed material produced by the double-tooth roller crusher features uniform particle size and low over-fining rate,thereby simplifying coal preparation processes and reducing investment and production costs.

coal crusher machine

1.Coal Crusher Machine

Feed Size: 80-1050 mm

Production Capacity: 7-300 tons/hour

Suitable Materials: Construction waste, pebbles, bluestone, limestone, granite, basalt, and other materials requiring handling operations.

Application Scope: Suitable for coal, metallurgy, mining, chemical, and building materials industries. Particularly suitable for crushing raw coal (including gangue) in large coal mines or coal preparation plants.

2.Working Principle

The coal crusher machine utilizes two wear-resistant alloy rollers rotating in opposite directions to generate high compressive force for material crushing. After entering the gap between the rollers (V-shaped crushing chamber), the material is crushed to the desired particle size through squeezing, shearing, and grinding, then discharged by conveying equipment.

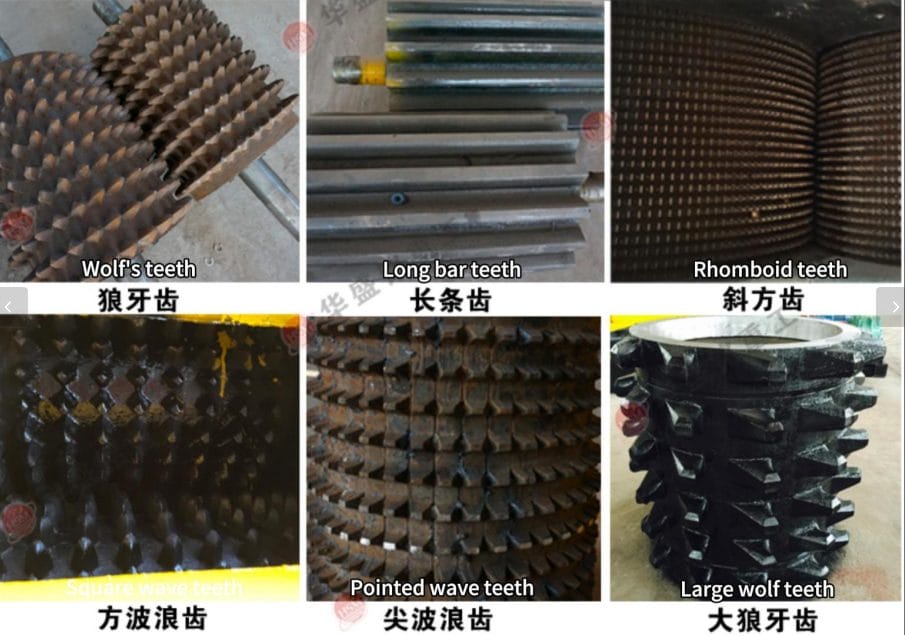

3.Tooth Profile Classification

coal crusher machine Tooth profiles can be categorized as: Long-strip teeth, Wolf teeth, Square wave teeth, Pointed wave teeth, Rhomboid teeth, Large wolf teeth (reinforced, enlarged, wear-resistant), etc.

4.Performance Advantages

1. Compact structure and small dimensions

2. Easy maintenance and convenient repair;

3. Suitable for dry, wet, muddy, and sticky ores

4. Uniform product size distribution

5. Minimal under-size and powdery products

6. Dual overload and iron protection