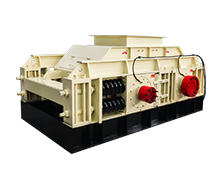

Double-roll crushers are fully capable of serving as crushers for steel slag and graphite crusher, and are often the preferred solution for crushing these materials. The key lies in tailored equipment configuration based on material properties—selecting appropriate roller skin materials, roller surface profiles, and necessary auxiliary equipment (such as magnetic separators) to address the hard abrasiveness of steel slag and the soft brittleness of graphite. When properly configured, double-roll crushers deliver exceptional performance in crushing steel slag and graphite, offering high efficiency, energy savings, and superior product quality.

steel slag and graphite crusher

1.Summary Comparison

| Features | Crushed Steel Slag | Crushed Graphite |

| Core Advantages | High-efficiency separation of metal and slag, excellent particle shape, minimal over-crushing | Extremely low over-grinding rate, anti-adhesion, controllable particle size |

| Roll Surface Selection | Ultra-wear-resistant tooth surfacesSmooth Rollers | Smooth Rollers |

| Cost-Effectiveness | 30% energy savings, extended wear part lifespan | Low power consumption, minimal maintenance costs |

| Material Properties | High hardness, high abrasion resistance, metal content | Soft, brittle, self-lubricating |