particularly in scenarios where product shape is critical and minimizing fines generation is a priority.

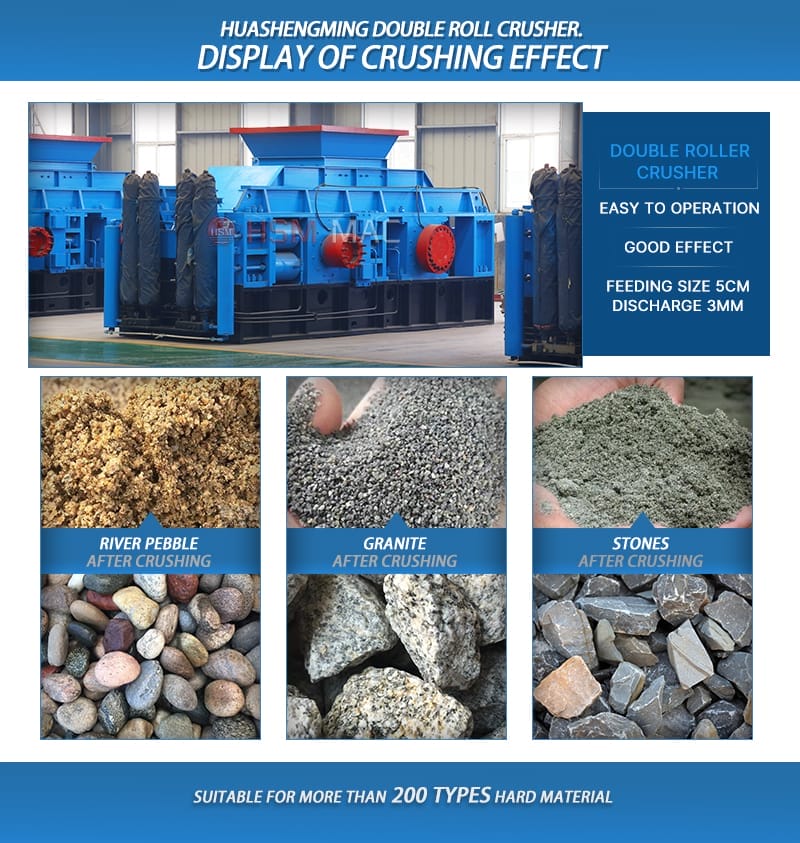

mineralized river bed sand gravel crusher

1.. What is “mineralized riverbed gravel”?

Mineralized riverbed gravel typically refers to:

A mixture of sand and gravel within natural alluvial deposits

Containing heavy minerals such as native gold, platinum group metals, cassiterite, ilmenite, and zircon

Particle size: 0–150mm, commonly 5–60mm pebbles + sand

Physical properties: High hardness (predominantly quartz, flint, granite pebbles), highly abrasive, often containing silt and water

2.Advantages of Double Roll Crushers (Why Are They Suitable?)

Excellent Particle Shape: Employing the principle of compression crushing, double roll crushers produce material particles predominantly in a cubic shape with low content of needle and flake particles. This is highly advantageous for applications requiring well-shaped aggregates, such as concrete aggregates.

Minimal Over-Grinding: Compared to hammer crushers or impact crushers, double roll crushers generate a lower proportion of powder (stone dust) during crushing. This better preserves the desired particle size of sand and gravel, increasing the yield of finished products.

Simple Structure, Easy Maintenance: The mechanical structure is relatively straightforward, making operation and maintenance relatively simple with fewer potential failure points.

Good Adaptability to Moisture- and Mud-Containing Materials: Double-roll crushers demonstrate superior adaptability to materials with slightly higher moisture and clay content (commonly found in riverbed gravel) compared to cone crushers, exhibiting reduced susceptibility to blockages. However, pre-treatment remains necessary for highly viscous materials.

Controllable particle size adjustment:

Output particle size can be conveniently controlled by adjusting the gap between the two rolls, offering excellent flexibility.

]]>

equipment for gold mining and processing, demonstrating significant advantages particularly in the medium and fine crushing stages.

ores for gold extraction and processing crusher

1. Technical Suitability: Feasibility of Gold Ore Crushing

Hardness and Material Compatibility

The double-roll crusher can process gold ores with compressive strength ≤250MPa, covering quartz vein-type gold deposits (typically 150-200MPa hardness) and

certain superhard rock types. Roll surfaces utilize high-chromium manganese steel or wear-resistant alloy (hardness HRC≥60), delivering over 2 years of service

life and significantly reducing maintenance costs.

Precision Particle Size Control

Hydraulic or mechanical roll gap adjustment (±1mm precision) enables stable output particle sizes between 1-5mm, meeting optimal sizing requirements for

leaching/flotation processes. Over-crushing rate <10% minimizes loss of fine gold particles.

Adaptability to Wet and Sticky Materials

The toothed roller design handles gold ore with high clay content or moisture content ≤35%, using shear force to strip viscous minerals and prevent jamming

(traditional jaw/cone crushers are prone to clogging).

2. Core Advantages: Competitive Edge in Gold Ore Crushing Applications

High Efficiency & Energy Savings

Layer compression crushing principle saves 30%-45% electricity compared to impact crushers, with power consumption per ton of ore at only 0.8-1.2 RMB;

Dual-motor independent drive mode allows flexible switching between single/dual-unit operation, further reducing energy consumption.

Overload Protection & Stability

Hydraulic springs automatically retract upon encountering hard objects (e.g., iron blocks), safeguarding core components;

Dual-safety system featuring hydraulic couplers + sensors ensures a failure rate **<1%, guaranteeing continuous production.

Environmental Compliance

Enclosed structure + pulse dust collection system keeps dust emissions **<10mg/m3 and noise ≤75dB(A)**, meeting green mining standards.

Versatility and Flexibility

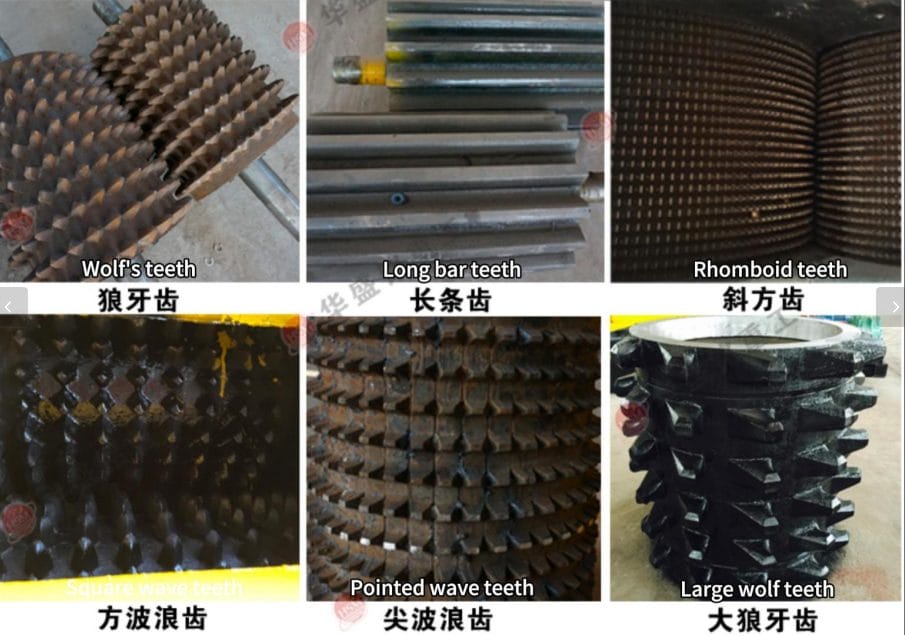

Interchangeable tooth profiles adapt to various gold ore types (e.g., oxidized, sulfide);

Tiered dual-tooth roller models integrate crushing and screening functions, streamlining process flows.

steel slag and graphite crusher

1.Summary Comparison

| Features | Crushed Steel Slag | Crushed Graphite |

| Core Advantages | High-efficiency separation of metal and slag, excellent particle shape, minimal over-crushing | Extremely low over-grinding rate, anti-adhesion, controllable particle size |

| Roll Surface Selection | Ultra-wear-resistant tooth surfacesSmooth Rollers | Smooth Rollers |

| Cost-Effectiveness | 30% energy savings, extended wear part lifespan | Low power consumption, minimal maintenance costs |

| Material Properties | High hardness, high abrasion resistance, metal content | Soft, brittle, self-lubricating |

]]>

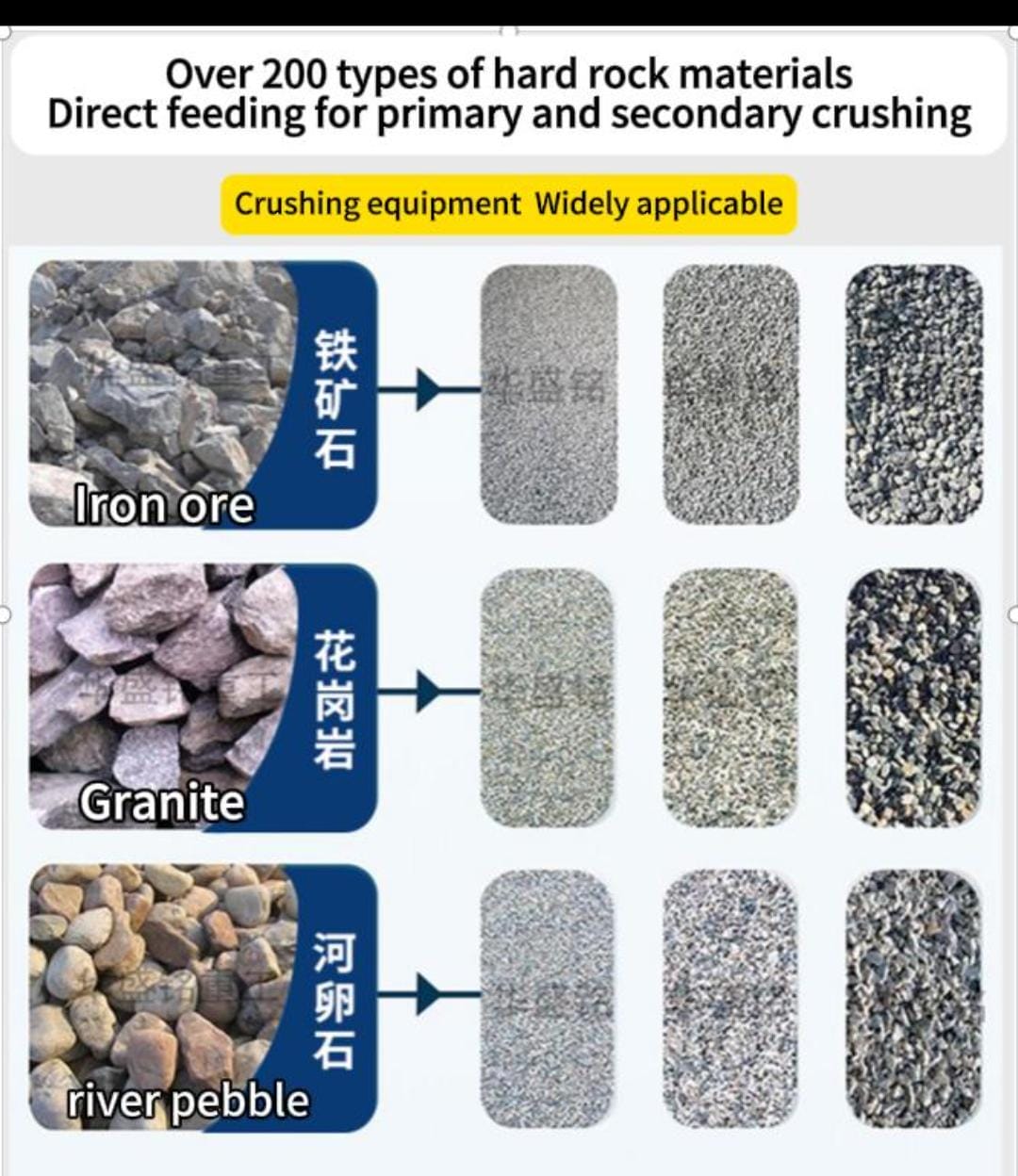

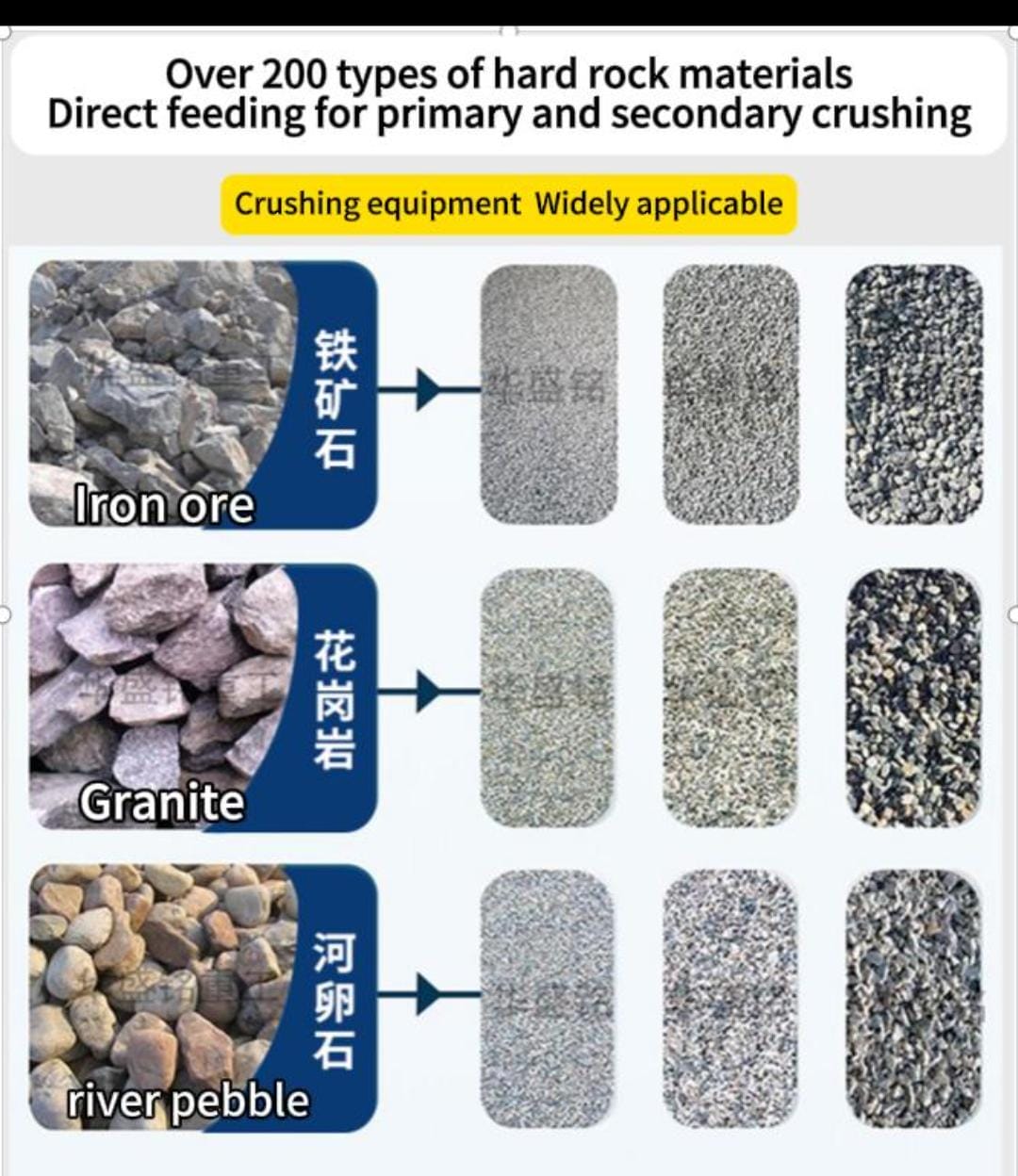

Iron Ore Crushers

1.What are the models of basalt sand making machines?

They can be categorized into large, medium, and small sizes based on model specifications.

2PGT400×250, 2PGT400×400, 2PGT610×400: With an hourly output of approximately 2-20 tons, these are small spring-loaded pebble sand making machines suitable for investment by small to medium-sized sand plants.

2PGT750×500, 2PGT800×600, with an hourly output of 10-50 tons, are medium-sized spring pebble sand makers. This model is suitable for new sand plants with relatively low investment costs.

2PGY750×500, 2PGY800×600, 2PGY800×800, 2PGY1000×800, with an hourly output of 20-80 tons, are medium-sized hydraulic pebble sand makers. Hydraulic models offer greater intelligence, higher output, and more cost-effective operation.

2PGY1000×1000, 2PGY1200×1200, 2PGY1500×1000, 2PGY1800×1000, 2PGY2000×1000, with hourly output of 80-400 tons, belong to the large flagship series of CNC pebble sand makers. Suitable for medium to large sand plants, they feature one-button start/stop for convenient and efficient operation.

2.Working Principle

The basalt sand-making machine operates on the principle of compression crushing. Its core consists of a pair of high-strength, wear-resistant counter-rotating rollers. During operation, raw basalt material enters the crushing chamber through the feed inlet and is subjected to intense compression by the two high-speed rotating rollers. The crushing force and output particle size are controlled by adjusting the distance between the rollers. Under the combined squeezing and shearing forces of the two rollers, the hard basalt is progressively crushed and refined into sand and gravel products featuring uniform particle shape and well-graded size distribution.

]]>

1.Advantages of Double Roll Crushers

95% Sand Production Rate

The double roll crusher builds upon traditional sand-making technology by integrating six intelligent systems, installation technology systems, finished product inspection systems, and more. This enhances its output, production capacity, and service life beyond other sand-making equipment. It is recognized as the premier stone crushing and sand-making machinery.

Easy Grain Size Adjustment

The double roll crusher allows for effortless adjustment of sand and gravel particle size.The working principle of the double-roll crusher is straightforward—essentially stone-on-stone crushing. Stones naturally falling within the chamber collide with stones accelerated and flung out by the impeller, achieving the crushing effect. When the accelerated stones collide with the naturally falling stones, a vortex is formed. During the return process, secondary crushing occurs, ensuring sufficient crushing force and frequency within the crushing chamber, resulting in higher product quality.

High Product Purity

The double-roll crusher eliminates the need for water to remove silt, thereby reducing costs. Unlike sand-making processes that require water for stone washing, this design not only achieves high product purity but also conserves water resources.

Concrete Crusher

1.Concrete Crusher

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

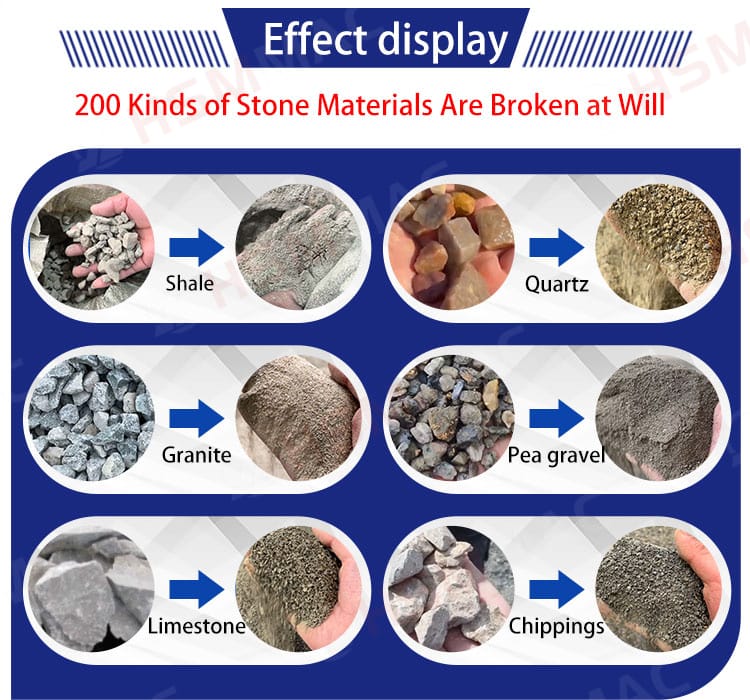

Suitable Materials:

River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

Application Scope:

Suitable for crushing in mining, cement, highway, railway, coal, metallurgy, building materials, and other industries.

2.Working Principle

The concrete crusher utilizes two independently driven roller shafts that rotate in opposite directions to generate crushing and grinding forces. Material enters through the feed opening and falls between the rollers, where it is crushed by the opposing rollers before naturally discharging. When encountering excessively hard or uncrushable material, the rollers automatically retract via hydraulic cylinders or springs, increasing the gap between them. allowing the hard or uncrushable material to pass through unharmed. The opposing rollers can adjust the pressure of the hydraulic cylinders or springs to control the final product’s particle size.

3.Performance Advantages

1. High Crushing Ratio and Strong Production Capacity

Utilizing the compression crushing principle, it achieves a high crushing ratio and is suitable for coarse, medium, and fine crushing of high-hardness materials such as coal, limestone, and slag. The machine operates smoothly with robust production capacity.

2. More Crushing, Less Grinding with Excellent Product Shape

By reducing feed particle size and improving the pulverization characteristics of feed material, it achieves the effect of more crushing and less grinding, enhancing production efficiency. The finished product is fine and of high quality.

3. Long service life and low operating costs

The roller shells are made of high-yield wear-resistant materials, featuring strong impact resistance and high wear resistance. Material loss during crushing is minimal, with low failure rates. This reduces subsequent maintenance and upkeep costs, resulting in low operating expenses and a long service life.

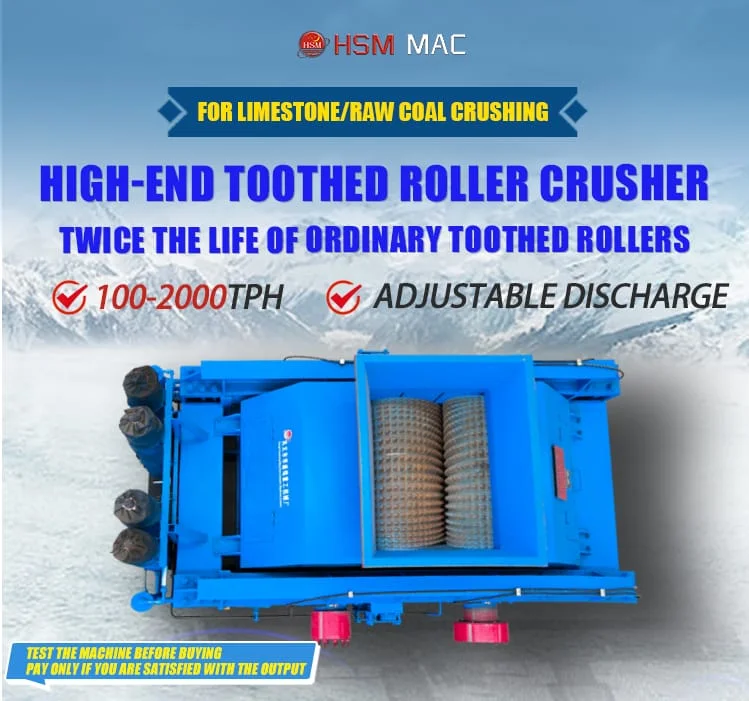

coal crusher machine

1.Coal Crusher Machine

Feed Size: 80-1050 mm

Production Capacity: 7-300 tons/hour

Suitable Materials: Construction waste, pebbles, bluestone, limestone, granite, basalt, and other materials requiring handling operations.

Application Scope: Suitable for coal, metallurgy, mining, chemical, and building materials industries. Particularly suitable for crushing raw coal (including gangue) in large coal mines or coal preparation plants.

2.Working Principle

The coal crusher machine utilizes two wear-resistant alloy rollers rotating in opposite directions to generate high compressive force for material crushing. After entering the gap between the rollers (V-shaped crushing chamber), the material is crushed to the desired particle size through squeezing, shearing, and grinding, then discharged by conveying equipment.

3.Tooth Profile Classification

coal crusher machine Tooth profiles can be categorized as: Long-strip teeth, Wolf teeth, Square wave teeth, Pointed wave teeth, Rhomboid teeth, Large wolf teeth (reinforced, enlarged, wear-resistant), etc.

4.Performance Advantages

1. Compact structure and small dimensions

2. Easy maintenance and convenient repair;

3. Suitable for dry, wet, muddy, and sticky ores

4. Uniform product size distribution

5. Minimal under-size and powdery products

6. Dual overload and iron protection

materials through compression. This roller crusher is suitable for fine crushing operations with feed sizes under 80mm and finished product sizes ranging

from 50 mesh to 20mm. Capable of processing materials with compressive strength ≤160MPa, it serves as an ideal production equipment for construction sand,

road-building sand, asphalt concrete, and cement concrete aggregates, suitable for transportation, construction, and other industries.

1.Roller Crusher

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

Suitable Materials

River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

Application Scope

Suitable for crushing in mining, cement, highway, railway, coal, metallurgy, building materials, and other industries.

2.Working Principle

The roller crusher performs crushing operations through roller wheels. Material enters between the rollers through the feed opening and is crushed by compression. A fixed gap exists between the two rollers. Increasing this gap produces larger output particle sizes, while the compression spring forces the gap to narrow, resulting in finer output. By adjusting the gap, the output particle size can be precisely controlled.

3.Performance Advantages

1 Simple and lightweight with powerful crushing force

2 High efficiency, low energy consumption, and superior output quality

3 Wide applicability and extended service life

4 Intelligent control for energy savings and labor reduction

The high-pressure roller mill is a simple-structured, reliable machine capable of fine and ultra-fine grinding operations with controllable fineness modulus. Our design specifically addresses current market demands for crushing hard materials, significantly enhancing crushing capacity compared to other high-pressure roller mills. It is suitable for fine crushing of hard and medium-hard materials with compressive strength below 250 MPa and moisture content under 10%. The high-pressure roller mill is also applicable in mineral processing, power generation, chemical, cement, refractories, abrasives, construction, and other industrial sectors for medium and fine crushing of various high-to-medium hardness ores, rocks, industrial waste residues, and other single raw materials or mixed materials blended with clay. It delivers superior performance compared to conventional high-pressure roller mills, particularly in producing crushed stone, coal, and coal-based grinding materials for the construction materials and power industries. It is also widely applicable in the steel grit crushing industry.

2.Why Choose Huashengming

Hydraulic system enables convenient and effortless roll gap adjustment while safeguarding overall machine safety.

Huashengming’s proprietary casting process significantly extends roller surface lifespan, achieving up to 20,000+ operating hours.

Steel rollers deliver high economic efficiency in pebble processing applications.

Suitable Materials

Stone Crusher Machine

Includes river pebbles, coke, coal, ceramic raw materials, quartz stone, limestone, mud shale, white chalk, bricks, slag, clinker, feldspar, coke feldspar, gypsum, salt, chemical raw materials, and other solid materials.

]]>

What is the working principle of smooth roll crusher

1. Core Crushing Mechanism

Material Entrapping and Compression

Material falls from the feed inlet between the two rollers and is drawn into the gap by roller surface friction. The two rollers (fixed and movable) rotate at low speeds in opposite directions (typically <4 m/s linear velocity), applying high compressive pressure to the material. This generates internal fractures and causes fragmentation.

Smooth Roll Characteristics: Featuring a smooth roll surface, this mechanism primarily relies on compression and grinding forces. It is suitable for medium-hard or brittle materials (e.g., limestone, coal), producing well-shaped particles with low over-crushing rates.

Overload Protection Mechanism

When non-crushable objects (e.g., iron pieces) enter, the movable roll automatically retracts via springs or a hydraulic system, widening the roll gap to discharge foreign objects before resuming its original position, preventing equipment damage.

Discharge Control

Crushed material discharges from beneath the roll gap, with particle size directly determined by the gap width (typically adjustable from 1-50 mm). A narrower gap produces finer output.

2. Key Structural Components

Crushing Rollers

Roller Shell Material: Huashengming employs high-chromium manganese steel or special alloys (hardness HRC ≥ 60), ensuring a wear-resistant lifespan of ≥ 2 years and reducing replacement frequency.

Roll Diameter to Width Ratio: Roll diameter is typically 9-22 times the material size (e.g., φ225-550 mm rolls for 25 mm material). The width-to-diameter ratio (L/D) ranges from 0.3 to 0.7 to ensure crushing efficiency.

Adjustment Mechanism

Mechanical Adjustment: Manually adjust the roll gap by adding or removing bearing housing shims (for compact models).

Hydraulic Adjustment: Huashengming mid-to-high-end models feature a hydraulic system with ±1 mm precision, enabling real-time dynamic adjustment.

Transmission and Drive

Dual Motor Drive: Each roller is driven by an independent motor, achieving counter-rotation via belts or gears to enhance crushing stability.

Long-Tooth Gear Protection: Traditional designs use long-tooth gears for power transmission, allowing roller gap adjustment during overload without gear damage but resulting in high noise and wear. New models adopt universal joints or dual-motor direct drive.

3. Particle Size Adjustment Mechanism

| Adjustment Methods | Principle | Applicable Scenarios |

|---|---|---|

| Adding or Removing Shims | Manually adjust the number of shims between bearings to physically alter the roll gap width | Small spring machines |

| Hydraulic Pressure Adjustment | Dynamically control the roll gap by adjusting hydraulic cylinder pressure in real time (accuracy ±1 mm) | Medium-to-large hydraulic presses |

| Intelligent Control System | The new Huashengming model features sensors that monitor material hardness, automatically adjusting the roll gap and rotational speed to maintain optimal crushing performance | High-end automated production lines |

4. Distinctive Technologies of Huashengming Products

Low-Speed High-Torque Design

Roll speed controlled at 75 r/min (e.g., 610×400 model) ensures thorough material compression, minimizes energy waste, and achieves 30%-45% lower specific power consumption than impact crushers.

Wear-Resistant Reinforcement

Roll shells utilize patented alloy materials with thickened treatment (60-80 mm thickness). Axial micro-adjustment (adding/removing retaining rings) prevents groove formation on roll surfaces, extending service life by over 3 times.

Intelligent Monitoring System

Real-time monitoring of temperature, pressure, current, and other parameters. Automatic alarm or shutdown upon anomalies. Supports remote control and data feedback.

5. Applicable Scenarios and Limitations

Suitable Materials:

Medium-hardness or softer brittle materials (compressive strength ≤160 MPa), such as limestone, coal, gypsum, glass waste, etc. Minimal sticking occurs when moisture content ≤8%.

Optimal Applications:

Building material sand production (output 1-3 mm, gradation meets Class II sand standards);

Glass recycling (crushing to 2-5 mm particles, over-crushing rate <10%).

Limitations:

Not suitable for high-hardness ores (e.g., granite requires specialized heavy-duty models);

Feed must be evenly distributed to prevent uneven roller surface wear.