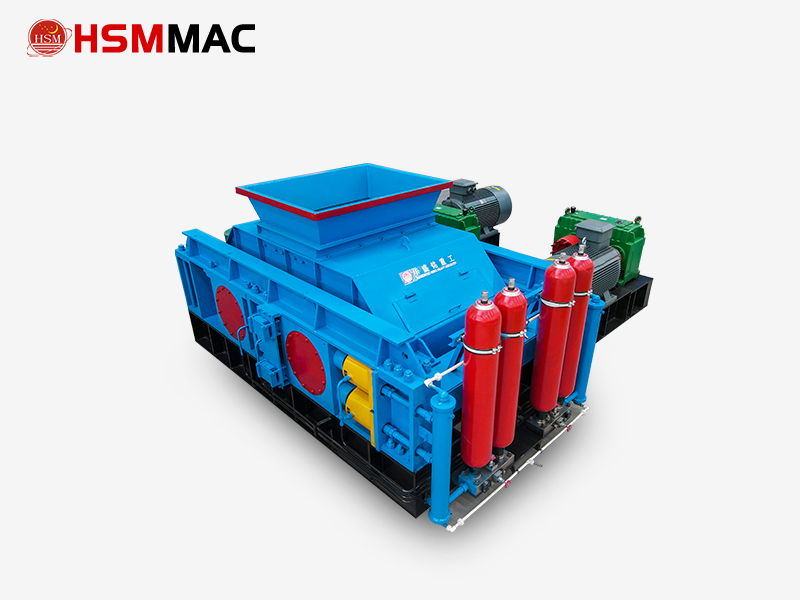

Huashengming Heavy Machinery Factory Produces A Diverse Range Of Coal Crusher.

2025-09-17

Huashengming Heavy Machinery Factory produces a diverse range of coal crusher, including tooth roller crushers, hammer crushers, and double-stage crushers, suitable for coal, mining, and building materials industries. Below is a summary of its core product lines and technical features: 1. Tooth Roller Crusher (Extrusion Crushing) 400×250 Model Parameters: Feed size ≤900mm, discharge size 30–200mm, processing capacity 150–200 tons/hour, power 22kW, weight 3.8 tons. Features: Dual-tooth roller design suitable for medium-hard materials (e.g., coal, stone). Price range: ¥1,800–2,350 (base model). 1200×1200 Model (Hydraulic Drive) Parameters: Feed size ≤60mm, discharge size ≤1mm, processing capacity 150 tons/hour, power 55kW, weight 5.5 tons. Features: Fully automatic hydraulic system, supports fine crushing to sand making, suitable for coke and coal gangue. Price range: approx. ¥19,800–3,000,000 (custom pricing). 1000×1200 Model Parameters: Feed size 700–950mm, processing capacity 180–220 tons/hour, roller length 750mm, weight 18.8 tons, power not disclosed. Features: Specialized for medium crushing of large materials (e.g., recycled asphalt), priced around ¥52,600. 2. Hammer Crusher (Impact Crushing) SCF600×600 Model Parameters: Feed size ≤110mm, discharge size ≤3mm, processing capacity 20–30 tons/hour, power 22kW (dual motors), suitable for wet coal blocks with moisture content <20%. Features: Screenless design prevents clogging, capable of crushing materials like ceramic tiles, priced…